Background

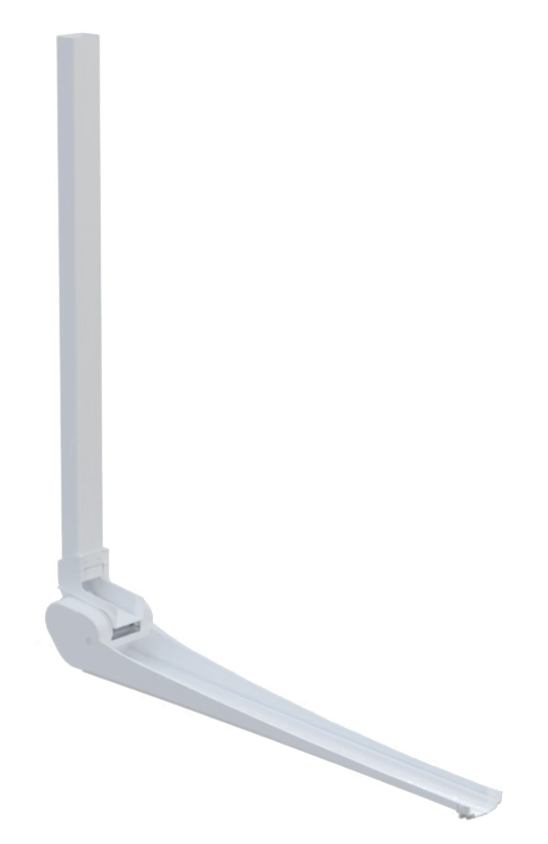

Rusten Gomez, the founder of AutoSpout, was frustrated with traditional downspouts that were too close to his home, causing flooding and pooling around the foundation. Determined to find a better solution, Rusten envisioned an auto-retractable downspout that would address these issues. He reached out to us at Corvus Engineering to bring his innovative idea to life.

Goals

AutoSpout needed to be:

- Compact, folding neatly into the downspout.

- Durable enough to withstand high winds.

- UV resistant and paintable to blend with users’ homes.

Key Challenges

Designing the AutoSpout presented several challenges:

- Ensuring the product was watertight.

- Creating a counterweight system that allowed the downspout to lower with minimal rainwater and spring back up when the rain stopped.

Approach

To tackle these challenges, Corvus Engineering employed a comprehensive approach:

- Sketches and 3D Modeling: Initial designs and detailed 3D models were created to visualize the concept.

- Finite Element Analysis (FEA) and Computer Simulations: These tools were used to analyze the product’s dynamics and overall strength.

- Collaboration with Manufacturers: We developed a unique living hinge design, enabling the AutoSpout to be molded as a single part while keeping crucial areas watertight.

Results

The end result was the successful creation of the AutoSpout. Rusten has sold thousands of units and recently secured a place for his product in a well-known big-box store, marking the beginning of a promising commercial journey.

Are you ready to bring your innovative product ideas to life? Contact Corvus Engineering today and let us help you transform your idea into a market-ready product.